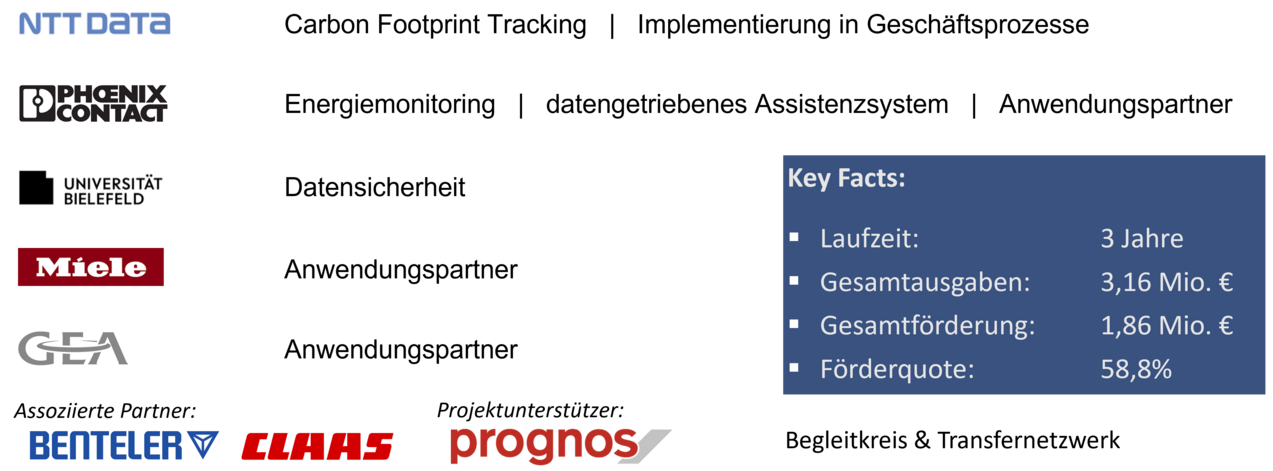

Climate bOWL will receive 1.86 million euros in funding from the Ministry of Economic Affairs, Innovation, Digitalisation and Energy of the State of North Rhine-Westphalia (MWIDE NRW) for three years from April 2022 as part of the "it's OWL" excellence cluster. In this project, researchers from the University of Paderborn, who are conducting interdisciplinary research at SICP - Software Innovation Campus, are working hand in hand with the Chair of Lightweight Automotive Design (also from the University of Paderborn), the University of Bielefeld and the companies NTT Data Business Solutions AG, GEA Westfalia Separator Group GmbH, Miele & Cie. KG and Phoenix Contact Smart Business GmbH. The total volume of the project is 3.16 million euros. Associated partners in the project are the companies BENTELER Automobiltechnik GmbH and CLAAS KGaA mbH, with Prognos AG acting as project supporter.

Research & application

SI-Lab | SICP - Software Innovation Campus Paderborn

On the University of Paderborn side, experts from the SI-Lab in the fields of energy efficiency and life cycle assessment (Energy Systems Engineering Group), knowledge modelling and analysis (Data Science Group) and production technology (Chair of Lightweight Automotive Design) are taking on the interdisciplinary challenges of the project. The Software Innovation Campus Paderborn (SICP), which is linked to the SI-Lab, deals with questions of data and software-driven innovations and thus creates an essential basis for the requirements-based design of future-oriented and intelligent socio-technical systems in the energy sector, among others. The SICP provides structures for the successful transfer of technology and knowledge into practice.

Department of Energy Systems Technology (EST)

The Department of Energy Systems Engineering conducts research in the field of energy-efficient production and the consideration of industrial energy requirements in the context of the energy transition, as well as the development of digital support systems for the energy transition. The researchers have many years of experience in these areas through their previous activities. This includes holistic energy efficiency analyses and the development of sustainable process heat concepts, the life cycle assessment of products and companies (PCF and Corporate Carbon Footprint), the development of automated RLM load profile analyses of companies, the development of support software for the design of energy supply systems in industry and preliminary work on automated energy demand monitoring in industrial production lines. The experience gained in the project will mainly be used in the activities of WP 3 and WP 4.

Chair of Lightweight Automotive Engineering (LiA)

The Chair of Lightweight Automotive Design has been conducting research for many years in the field of process development and optimisation for the efficient processing of metallic materials (Marten 2017) (Pfeifer et al. 2019), plastics (Stallmeister et al. 2019), hybrid materials (Wang et al. 2018) and also bio-based materials (Schweizer et al. 2020). In addition to expertise in the field of energy, ecological and technological considerations of manufacturing processes, LiA has experience in the life cycle assessment of manufactured components, taking into account the entire life cycle (Hielscher et al. 2020). In addition, LiA is involved in the NRW research college "Light - Efficient - Mobile" and thus makes a significant contribution to overcoming social challenges such as resource efficiency and environmentally friendly mobility through an interdisciplinary research approach (Weiß-Borkowski et al. 2018). The Chair contributes its experience to WP 3.

Data Science group

The working group Data Science headed by Prof Dr Axel-Cyrille Ngonga focuses its research on issues relating to the life cycle of knowledge graphs and machine learning methods. Research results on knowledge extraction include the development, implementation and testing of methods for the (weakly) supervised recognition of entities and relations in unstructured and semi-structured data. Prof Ngonga received the Best Paper Award at ISWC 2014 for his research on agnostic disambiguation of entities. He investigated unsupervised and (weakly) supervised methods for the integration of knowledge graphs. This resulted in the LIMES tool, which has already been honoured several times, e.g. with the Best Paper Award of the ISWC 2011, and provides a good basis for the work in the development of the assistance system.

Cognitronics & Sensors group

The Cognitronics & Sensors group at Bielefeld University involved in the project is part of the Research Institute for Cognition and Robotics (CoR-Lab), which brings together Bielefeld University's research activities in the fields of cognitive science and artificial intelligence. The group's central research goal is the systematic design of resource-efficient architectures for distributed cognitive systems that are characterised by a decentralised organisation and independently adapt their system resources to changing environmental conditions. Areas of application include cognitive robotics, cognitive edge computing for automation technology (Industry 4.0, Smart Home) and self-organising sensor networks. News projects include the it's OWL innovation project I4.0AutoServ, the EU project VEDLIoT and two BMBF projects in the field of trustworthy electronics (VE-ASCOT, VE-DIVA-IC). Relevant preliminary work includes the targeted design of resource-efficient machine learning methods and their performance evaluation, which have been incorporated into the ML toolbox of the ML4Pro² project and are available to this project. In the project, Bielefeld University is focussing on data collection, data analysis and method development.

GEA Westfalia Separator is one of the world’s largest systems suppliers for the food, beverage and pharmaceutical sectors. Our portfolio includes machinery and plants as well as advanced process technology, components and comprehensive services. Guided by a strong sense of purpose, our more than 18,000 dedicated employees work to enhance the sustainability and efficiency of production processes globally.

GEA Westfalia Separator is part of the GEA Group, which generated sales of more than EUR 4.7 billion in the 2021 financial year with more than 18,000 employees. In view of the increasing challenges to achieve climate targets, both products and processes as well as the company's own production processes are constantly being optimised with regard to the resulting GHG emissions.

The separators and decanters manufactured by GEA are currently used for more than 3,000 different applications. The operating parameters with which the plants are operated depend on the raw materials to be processed and their seasonal fluctuations. To counter these fluctuations, the centrifugals are equipped with a variety of actuators. Some settings, such as the speed setting, have a significant influence on energy consumption. Recording the operating parameters is a prerequisite for defining the fields of action for GHG-reduced operating strategies. GEA has already equipped more than 700 plants with data acquisition. The data is processed in the GEA Cloud.

The project is investigating how the relevant data can be processed and made available to customers. Based on these findings, new generations of centrifugals, assistance systems and operating strategies will be developed. The success of the project will make a decisive contribution to the competitiveness of future products.

Miele is the world's leading manufacturer of premium domestic appliances as well as appliances for commercial laundry care and medical technology. With its own sales companies and importers, Miele is represented in around 100 countries. As an independent, family-owned company, Miele strives to be a leader in quality and technology. Sustainability has been a top priority at Miele since the company was founded, which is reflected in the durability and energy efficiency of its appliances. Since 1990, the company has consistently pursued site-specific sustainability goals and publishes its own sustainability report every two years. In 2011, Miele adopted a global sustainability strategy and won the German Sustainability Award in 2014.

Against the backdrop of climate change, resource scarcity, changing customer needs and stricter regulatory framework conditions, Miele undertook a comprehensive revision of its sustainability strategy last year.

On the way to achieving its goals, Miele is currently facing two key challenges, which are to be addressed by the planned research project:

- Transparency: A prerequisite for the decarbonisation of the company is complete transparency regarding GHG emissions. Miele has already carried out initial analyses in this area. However, there is a lack of consistent and system-supported carbon accounting, particularly in the supply chain and product utilisation (Scope 3).

- Portfolio of measures: The reduction targets must be backed up with specific measures. The initial focus here should be on decarbonising the company's own production plants. The aim is to identify suitable measures in terms of their leverage effect, evaluate costs and ultimately implement the measures.

As part of the project, the washing machine product group will be analysed as an example. On the one hand, transparency is to be created regarding the carbon footprint from the supply chain, through production to use and disposal. On the other hand, the company's own production network consisting of the washing machine plant in Gütersloh and the supplier plant in Warendorf will be analysed with regard to efficiency measures. Warendorf is the company's own competence centre for plastics technology (Technology Center Plastics) with very energy-intensive processes. Among other things, the centre manufactures washers, switch panels and doors for washing machines.

NTT DATA Business Solutions AG, headquartered in Bielefeld, Germany, is the leading international SAP consultancy and IT service provider for medium-sized companies.

NTT DATA Business Solutions has been part of the NTT DATA Group of Japan since 2008. NTT DATA Business Solutions employs more than 12,000 people worldwide and generated a turnover of around 1.24 billion euros in 202.

As a globally successful company, NTT DATA Business Solutions advises a large number of medium-sized companies and hidden champions through to corporations in the manufacturing industry and is very familiar with the complex requirements of these companies. Sustainable value creation and achieving climate neutrality is an increasingly important goal and a key challenge in this industry. This is not just about the company's own production, but also about co-operation across company boundaries, as sustainability is not only being integrated as a performance indicator, but increasingly as a new dimension of success in business processes and decision-making. As a global consultancy, NTT DATA therefore offers suitable solutions and approaches to support customers across continents on the path to climate neutrality.

The first important step is to precisely determine and measure greenhouse gas emissions (GHG) for individual products, in individual processes and then along the entire value chain. In this way, suitable measures for process and product optimisation to reduce GHG and energy consumption can be developed and implemented in a targeted manner. NTT DATA Business Solutions AG is using its extensive and award-winning SAP expertise to implement solutions and tools such as "Carbon Footprint Analytics", which SAP AG is developing as part of its "climate 21" initiative, supplemented by its own solutions, as part of the research project.

The industrial partners GEA, Miele and Phoenix Contact, as well as the research partners Paderborn University and Bielefeld University, are excellently suited to develop concrete solutions for measuring GHG along the value chain and far-reaching solutions for creating measures to reduce consumption, which NTT DATA Business Solution will later make available to other customers and companies via transfer and services. This marketing and transfer of the results and the know-how gained is an important aspect for NTT DATA Business Solutions, in addition to the joint research.

Phoenix Contact Smart Business GmbH stands for cloud services and data analytics in industrial automation. A proprietary IIoT platform "Proficloud.io" and application-oriented smart services are being developed so that companies can fully exploit the benefits of digitalisation and the Industrial IoT. The goal: maximum simplicity, maximum transparency. Day-to-day business: smartification made easy!

In addition to other innovative smart services, Phoenix Contact Smart Business GmbH has developed a cloud application for energy management called EMMA Service over the past two years, which has been available to book in the Service Store since April 2021. EMMA Service (Energy, Monitoring, Management, Analytics) focuses on the energy manager as the user and is ideally tailored to their needs in the fields of measurement, analysis and reporting. With a simple, intuitive design, the EMMA Service offers a flexible range of functions in the field of electrical energy and performance data visualisation for monitoring, analysing and evaluating this data.

As part of climate bOWL, the basic functionalities of the EMMA service are to be utilised so that the energy data obtained can be used to determine THGE. In addition, the system is to be expanded so that it meets the requirements of a holistic carbon footprint tracking system. In addition to the Smart Service EMMA Service, Phoenix Contact is also developing hardware components that are to be used as measuring devices in the aforementioned scenario. Engineers will support the technical developments in the project and energy management specialists will also be on hand to provide advice. In addition, experience from production will be incorporated by using the measures currently implemented in the company's own operations to support the activities carried out. The Phoenix Contact Group and all its subsidiaries aim to achieve CO2-neutral production by 2030.

Project management

Head -

Office: P6.2.073

Phone: +49 5251 60-2185

E-mail: henning.meschede@uni-paderborn.de

Project members

Energy efficiency in the context of strategic decarbonization of the industry

Office: P6.2.07.2

Phone: +49 5251 60-4546

E-mail: marius.naumann@uni-paderborn.de

Head -

Office: F1.225

Phone: +49 5251 60-1761

E-mail: axel.ngonga@uni-paderborn.de

Team Simulation and Method Development

Office: Y1.217

Phone: +49 5251 60-5163

E-mail: moritz.ostermann@uni-paderborn.de

Team leader of energy transition in industry and urban heating planning, industrial and commercial energy conversion technologies for regional,…

Office: P6.2.07.2

Phone: +49 5251 60-4138

E-mail: florian.schlosser@uni-paderborn.de

Coordinator - R&D Manager - Digital Business

Office: ZM2.A.03.25

Phone: +49 5251 60-5240

E-mail: weskamp@sicp.de